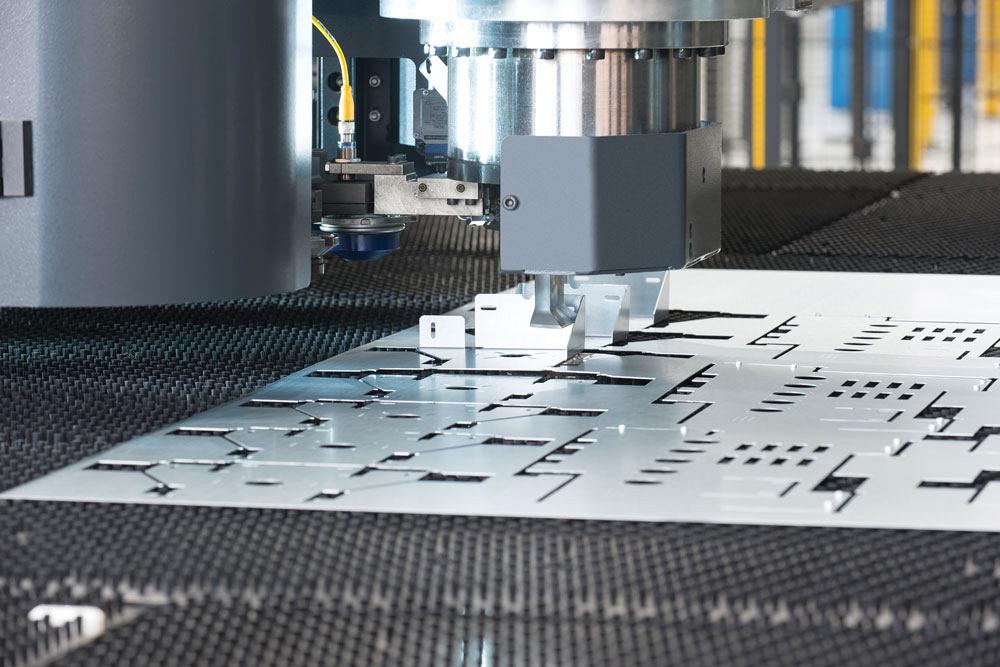

Punch Presses

Punch presses are machines designed to punch holes or shapes into sheet metal or other materials using a punch and die mechanism. The punch press applies force to the material, which is sandwiched between the punch and die, creating holes or forming desired shapes. Punch presses are commonly used in industries such as metal fabrication, automotive, and electrical manufacturing for tasks like making holes, embossing, blanking, and stamping.

Benefits of Punch Presses:

Using punch presses, also known as punching machines or punch presses, offers several benefits in various industries. Here are some advantages of using punch presses:

High Production Speed

Punch presses are known for their high production speeds. They can perform rapid and repetitive punching operations, making them suitable for high-volume production environments. This efficiency can significantly increase productivity and output.

Versatility

Punch presses can be used for a wide range of operations, including punching, blanking, piercing, forming, embossing, and bending. They can work with various materials such as metal sheets, plastics, and even leather. With different tooling options, punch presses offer versatility in creating different shapes and designs.

Material Efficiency

Punch presses maximize material utilization and minimize waste. They can be programmed to optimize the layout of parts on the material, reducing scrap and maximizing the number of parts produced from a single sheet. This efficiency in material utilization can lead to cost savings and sustainability benefits.

Quick Setup and Changeover

Punch presses often feature tooling systems that allow for quick setup and changeover. This flexibility enables operators to switch between different punching operations or part configurations efficiently, reducing downtime and increasing production agility.

Cost-effectiveness

Punch presses can be cost-effective for high-volume production. Once the initial tooling is set up, the cost per part decreases significantly, making them economically advantageous for large-scale manufacturing. Additionally, punch presses require minimal labor and can operate continuously, further reducing production costs.

Accuracy and Precision

Punch presses deliver precise and accurate results. They use specialized tooling with sharp punches and dies to ensure consistent and tight tolerances. This precision is crucial in industries where accuracy and repeatability are critical, such as automotive, electronics, and aerospace.

Automation and Integration

Punch presses can be easily integrated into automated production lines, allowing for unmanned operation and increased efficiency. They can be equipped with robotic systems for material handling, part sorting, and other automated processes, reducing the need for manual intervention and improving overall productivity.

Safety Features

Modern punch presses are equipped with safety features to protect operators and prevent accidents. These features include safety light curtains, two-hand controls, emergency stops, and interlocking mechanisms, ensuring safe operation and compliance with safety regulations.